Grosch Irrigation Company Inc.

Grosch Drilling / Exploration GIC Water Systems

| Well Rehabilitation | ||||||||

| Our time tested methods of rehabilitation can often bring back production from older wells that have decreased in yield over the years. As you may already know there are many ways to rehabilitate wells. Organic acids are often used, but applying chemicals alone can be in some situations, a waste of money. At Grosch we are able to attack the problem using a variety of methods such as acidizing and surge block to the new environmentally safe AirBurst treatment. Please feel free to contact us for information on how to revive your tired old well. | ||||||||

|

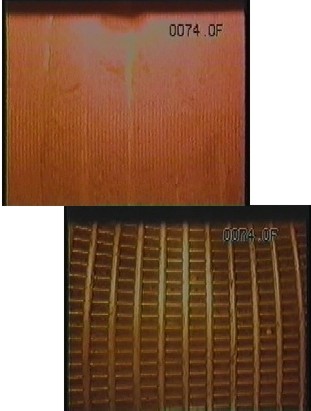

Video Inspection Is your well not producing what it should? Our full color video camera produces an excellent view of wells from 6 to 36 inches in diameter. High intensity laps with variable adjustment light up the hole like daylight. Our system contain a built in VCR for creating a well video for your records. This is very useful in troubleshooting for well rehabilitation, checking integrity of well casing, or retrieving material from the well. |

|

|||||||

|

|

|||||||

|

||||||||